10-TOOTH COGS FOR THE WIN

Demystifying eTap AXS X-Range Gearing

Cogs on the small end of the cassette have been shrinking ever smaller throughout the evolution of multi-speed road bikes, and for good reason. With X-Range gearing found on SRAM RED and Force eTap AXS, that number is now down to 10 teeth.

Why?

Interestingly, every time that little cassette cog got smaller, it was for the same reasons. For example, front shifting requires big changes to your pedaling cadence and breaks up the rhythm of your ride. These shifts cost rider efficiency and detract from the riding experience. Smaller cogs (like our X-Range 10 tooth cog) allow you to use smaller chainrings to get to the same top speed. If the largest cog on the cassette remains the same size, you can stay in the big ring longer and limit the number of front downshifts you have to make.

Another benefit of shrinking the size of the large chainring is that it reduces the difference in the number of teeth between the two chainrings. This means smoother front shifting while limiting the cadence disruption those shifts cause during your ride. And you can do this while also adding gear range to the drivetrain. We’ve taken advantage of each of these benefits of 10-tooth cogs in our eTap AXS groupsets. It’s what sets X-Range apart from what’s available with traditional road gearing.

Additionally, X-Range offers WorldTour level riders an exclusive gearing advantage over competitors. Some of our pros opt to maintain the same size chainrings found in traditional drivetrains with 11-tooth start cassettes. This gives them an additional 10-tooth cog for a higher top speed. While mere mortals need bottom-end bailout gears, these riders need top-end bailout gears to win races!

Photo by Getty Images

Is there a downside to 10-tooth cogs?

A common concern expressed by cycling tech enthusiasts is that the smaller cogs get, the less efficient a drivetrain becomes, due to increases in friction between the chain and cog and the added rotation required at each chain link. However, something that is often misunderstood in these discussions is that this efficiency concern only reliably applies when every other component in the system is the same. In other words, a true apples-to-apples comparison requires using all the same components, except the cog you are testing. Outside of applied science discussion circles, this critically important point is often missed.

So, while it’s a scientific fact that (all things being equal) smaller cogs are less mechanically efficient than bigger ones, another fact remains; when comparing 11-tooth start SRAM 11-speed road groups and 10-tooth start SRAM 12-speed road groups, nothing is equal because every component in the system is different in multiple key aspects.

An inexhaustive list of these differences include the following:

- Chain — Every piece of the chain has different dimensions

- Derailleur pulley tooth count — eTap AXS rear derailleur pulleys are one tooth larger

- Gear teeth shape and thickness

- Chainring design

Put it to the Test

So, for a real apples-to-apples comparison, it's best to compare cogs on the same 12-speed drivetrain. Our internal testing showed that the drop in efficiency between the 11 and 10-tooth cogs came to 1%. To put that in perspective, on the same drivetrain, the drop in efficiency between the 12 and 11-tooth cogs is 0.87%. This means that the delta between the two comes out to just 0.13%. So, the reality is that efficiency doesn't fall off a cliff when riding in the 10-tooth cog.

With that said, admittedly this data doesn't fully resolve the question of efficiency between 11 and 10-tooth cogs, because in order to make an equivalent comparison the gear ratio should be the same between the two. To get the same gear ratio on a 10-tooth cog when using an 11-tooth cog, you need a chainring that is roughly five teeth larger. As we know, this larger chainring provides the efficiency benefit of lower chain tension in the upper drivetrain for the same load. But we’re looking at tenths of a percent in added efficiency due to that. This is because the larger ring increases the number of links required to drive each rotation of the rear wheel. More links rotating equals more friction, so the increased chainring size doesn’t have as much benefit as it seems. So with all else held equal, more chain links moving through the lower drivetrain (the low-tension section where the chain exits the chainring and then goes through the rear derailleur pulleys) incurs more losses, offsetting a portion of the benefit gained in the upper portion of the drivetrain from larger chainrings and cogs.

The point being, we're talking about very small numbers that are largely theoretical outside of a lab test. Out on the road, chain lubrication and cleanliness have a far greater effect on drivetrain efficiency than what can be gained by using an 11-tooth start cassette. Plus, with a traditional cassette, you miss out on other real-world time-saving benefits, like making fewer front shifts.

Looking at the Big Picture

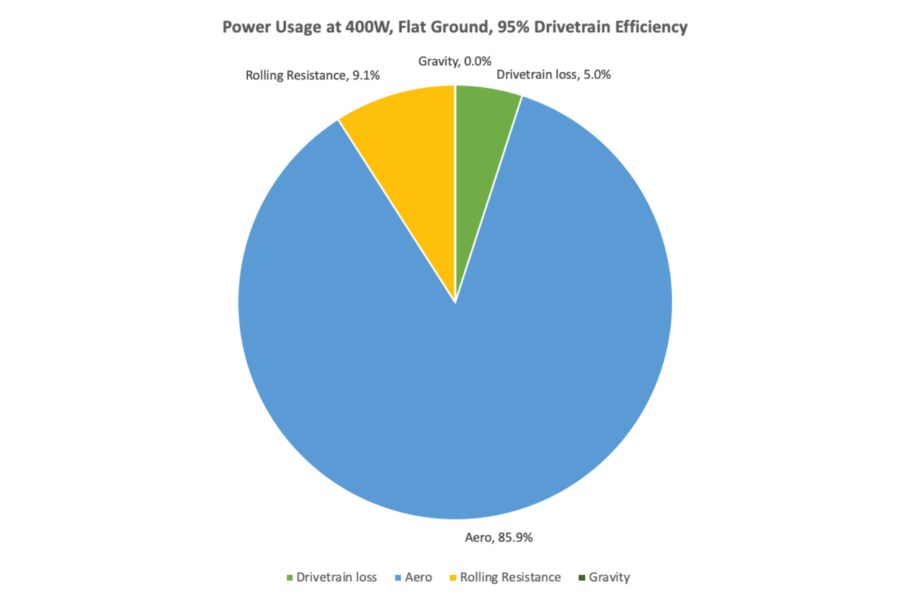

When thinking about the topic of drivetrain efficiency as it relates to small cogs, keep in mind that any time you are using a 10-tooth cog, you are riding at 44kph or more. At these speeds, aero drag makes up about 86% of the resistance a rider has to overcome. The remaining sources of resistance are drivetrain friction and rolling resistance, which come out to just about 5% and 9% respectively when pedaling at 400 watts on flat ground. This means that a 1% improvement in drivetrain efficiency at these speeds would amount to 0.05% less resistance a rider has to overcome (aero + drivetrain + rolling resistance). That's just half of one-tenth of a percent.

Efficiency aside, few riders use their smallest cog for very long in a given day’s riding.^ To put that in perspective, if a rider living in a hilly area spent the same amount of time in their highest gear as they spent reading this article, they would need to ride hundreds of miles to encounter enough terrain to use that gear (actually pedaling, not coasting) at a normal descending cadence.

Learn How X-Range Gearing Can Work for You

Whether you are looking for more range, tighter steps between gears, or fewer and smoother front shifts; the X-Range gearing found on our eTap AXS groups has all of them. Selecting the right X-Range drivetrain setup for you is simple. We’ve put together an easy-to-use gear calculator below for selecting a drivetrain option you’re sure to love.

^How long is ‘not very long’? One of the beauties of AXS is that our free online AXS Web data platform offers AXS groupset owners time-in-gear data. So, if you come across someone in your area that has eTap AXS, they can tell you exactly how much they use their 10-tooth cog for some real-world gearing input on the roads you both ride.