HYDRAULIC BRAKE HOSES

Which SRAM Hydraulic Brake hose kit do you need?

Hydraulic Brake Hoses are specific to your brake system and utilize different mounting styles depending on the groupset that you are using. Proper identification is crucial for the correct function and performance of your brakes. Below are the hydraulic line kits that SRAM produces; please remember that these will depend on your brake model.

If you know what you are already looking for, feel free to use the links below:

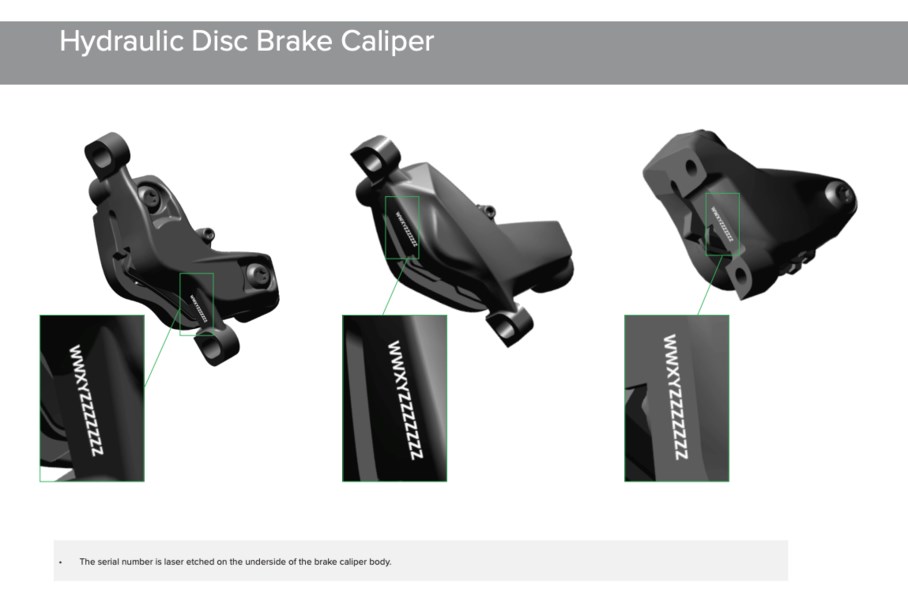

STEP ONE: Confirm brake model

The easiest way to find your brake model is to use the SRAM Service website and search for the serial number from your component. Our service website will allow you to input your serial number. The image below shows you where the brake calipers display the serial number.

**Hot tip is to use your phone with flash to take a photo and read the serial number off of the photo.

Simply enter your service number into our service website

STEP TWO: Select the Hydraulic Brake Hose kit for you brakes.

After confirming your brake model, it is time to determine which hose kit you require. We recommend double-checking the hose ends on your existing brake hoses to ensure that the new kit utilizes the correct fittings. There are five kits, so please check that they match your existing brake.

Below is a list of all the SRAM and AVID Hydraulic Brake Hose kits available as replacements. A diagram of the hose fittings and a photo of the entire kit and contents are included.

Double Compression

The double compression hose offers shortening options at both the lever end and caliper. For road bikes, this can assist in sizing lines without removing the bar tape.

- Part Number: 00.5318.036.000

- Description: AM DB HYD HOSE 2000MM DBL COMPRESSION

- Compatible Hydraulic Brake Fluids: DOT 4 or 5.1 or Maxima Mineral Brake Oil*

- Applicable Brake Models: AVIDCode/R, Elixir1/3, Juicy3, DB 1/3/8, LevelULT/TLM(B1), Level/T,Guide RE,G2 RE/RS/R, S900 2P(Red,Force,Rival Two-Piece-Caliper eTapAXS), Level 2P Stealth Ultimate & Silver, Level 4P Bronze, Code Stealth Bronze (2023+), APEX D1 (2023+) and Maven Bronze.

- Parts included in the kit: Specific brake line and necessary seals, 2x short (road) compression nuts, 2x long (MTB) compression nuts, 2x SRAM Barb, 2x SRAM Olive, Caliper compression nut boot, 2x external cable holders, 2x stem mounted cable holders, T8 Torx key for barb installation.

- Can't locate a Double Compression kit? Fear not, any SRAM Hydraulic Brake Hose kit can be substituted once the respective Banjos have been removed

* Although Hydraulic Brake Hose Kits are compatible with DOT and Mineral Oils, these kits cannot be cross-contaminated once one fluid has been selected and bled into the system. When used together, Mineral and DOT fluids interact in a way that can cause a lack of performance in the Hydraulic Brake System that could lead to serious injury or death. The interaction is a swelling of the internal layer of the Hydraulic Brake Hose, which limits the amount of fluid movement in the system.

Brake systems are designed for a specific fluid and the fluid type cannot be changed. Only use the fluid your brake system was designed to work with.

Double Compression 2

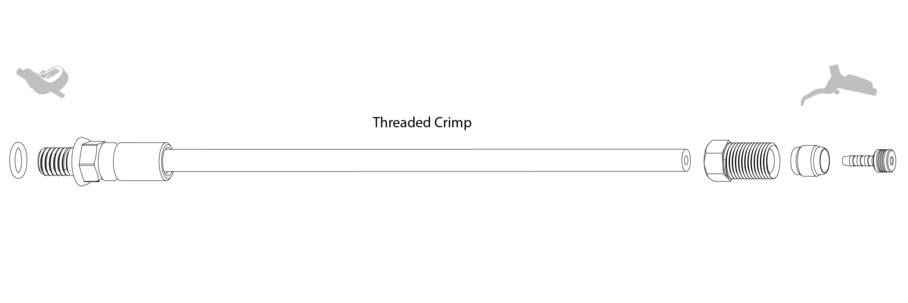

Threaded Crimp

The Threaded Crimp line is only adjustable at the lever and features a fixed long crimp at the caliper end to offer protection of the brake line, which is ideal for mountain bikes.

- Part Number: 00.5318.037.000

- Description: AM DB HYD HOSE 2000MM THREADED CRIMP

- Compatible Hydraulic Brake Fluids: DOT 4 or 5.1

- Applicable brakes: Elixir 5, Elixir 7, Elixir 9, Elixir CR, Elixir X0, Elixir CR Mag, Guide RSC (A1), Guide RS (A1), Guide R (A1), DB5, Level T, Level Stealth 2P Bronze (2023+)

- Parts included in the kit:

Specific brake line and necessary seals, 2x long (MTB) compression nuts, 2x SRAM Barb, 2x SRAM Olive, Caliper compression nut boot, 2x external cable holders, 2x stem mounted cable holders, T8 Torx key for barb installation. - Can't locate a Double Compression kit? Fear not, any SRAM Hydraulic Brake Hose kit can be substituted once the respective Banjos have been removed

Threaded Crimp line

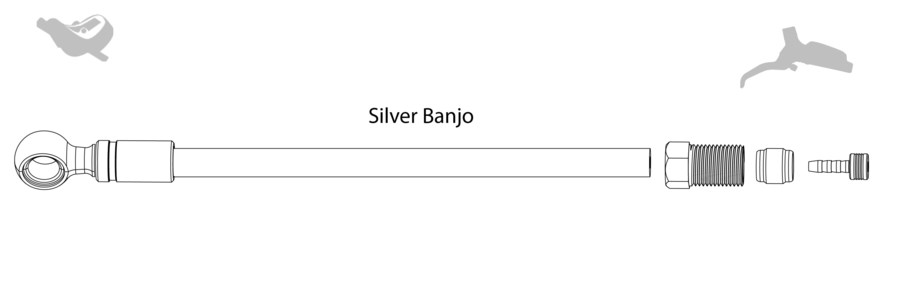

Silver Banjo

The silver banjo offers adjustment of the brake line length only at the lever body since the banjo is crimped onto the caliper end of the hose and cannot be replaced. The banjo also offers adjustment for line angle at the caliper as well as an adjustment at the lever for hose length.

- Part Number: 00.5318.038.000

- Description: AM DB HYD HOSE 2000MM SILVER BANJO

- Compatible Hydraulic Brake Fluids: DOT 4 or 5.1 or Maxima Mineral Brake Oil*

- Applicable Brakes: XX, Juicy Ultimate, Juicy 7, Juicy 5, Guide Ultimate (B1), Guide RSC (B1), Guide RS (B1), Guide R (B1), Guide T (A1), G2 Ultimate, G2 RSC, Level 4P Ultimate & Silver, Maven Ultimate and Silver (Be aware the correct 'green' seal must be used when using this hose kit with our mineral oil brakes).

- Parts included in the kit: The specific brake line and necessary seals, 2x long (MTB) compression nuts, 2x SRAM Barb, 2x SRAM Olive, Caliper compression nut boot, 2x external cable holders, 2x stem mounted cable holders, T8 Torx key for barb installation.

- Can't locate a Double Compression kit? Fear not, any SRAM Hydraulic Brake Hose kit can be substituted once the respective Banjos have been removed

* Although Hydraulic Brake Hose Kits are compatible with DOT and Mineral Oils, these kits cannot be cross-contaminated once one fluid has been selected and bled into the system. When used together, Mineral and DOT fluids interact in a way that can cause a lack of performance in the Hydraulic Brake System that could lead to serious injury or death. The interaction is a swelling of the internal layer of the Hydraulic Brake Hose, which limits the amount of fluid movement in the system.

Brake systems are designed for a specific fluid and the fluid type cannot be changed. Only use the fluid your brake system was designed to work with.

Silver Banjo Hose Fittings

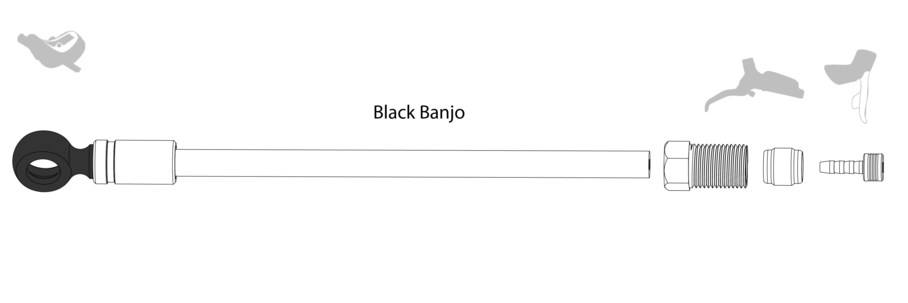

Black Banjo

The Black Banjo line is seen on road and mountain bike calipers. The black-colored head sits on the caliper and is slimmer than the silver Banjo above. The Banjo also offers adjustment for line angle at the caliper and at the lever for hose length.

- Part number: 00.5318.039.000

- Description: AM DB HYD HOSE 2000MM BLACK BANJO

- Compatible Hydraulic Brake Fluids: DOT 4 or 5.1

- Applicable Brakes: Level ULT (A1), Level TLM (A1), CODE R/RS/RSC (B1), Red eTap HRD, S900 Monoblock and Code Stealth Ultimate, Silver and Bronze.

- Parts included in the kit: Specific brake line and necessary seals, 2x short (road) compression nuts, 2x long (MTB) compression nuts, 2x SRAM Barb, 2x SRAM Olive, Caliper compression nut boot, 2x external cable holders, 2x stem mounted cable holders, T8 Torx key for barb installation.

- Can't locate a Double Compression kit? Fear not, any SRAM Hydraulic Brake Hose kit can be substituted once the respective Banjos have been removed

Black Banjo Fittings

Beveled Banjo

The Beveled Banjo system utilizes 11-speed road brakes exclusively; the portion on the shifter is fixed and bolts directly into the fluid body of the lever. As road bikes will generally come fitted with handlebar tape, this design means that the lines can be shortened at the caliper.

- Product Number: 00.5318.040.000

- Description: AM DB HYD HOSE 2000MM BEVELED BANJO

- Compatible Hydraulic Brake Fluids: DOT 4 or 5.1

- Applicable Brakes:Flat Mount; Red22, Force22, Rival22, Force 1, Force CX1,Apex1 HRD, S700 and Rival 1.

- Parts included in the kit: Specific brake line and necessary seals, 2x short (road) compression nuts, 2x long (MTB) compression nuts, 2x SRAM Barb, 2x SRAM Olive, Caliper compression nut boot, 2x external cable holders, 2x stem mounted cable holders, T8 Torx key for barb installation.

- Can't locate a Double Compression kit? Fear not, any SRAM Hydraulic Brake Hose kit can be substituted once the respective Banjos have been removed.

Beveled Banjo Hose Fittings

STEP THREE: Installation & bleed

The service and installation of SRAM Hydraulic Disc Brake systems and their spare parts require specific tools, fluids, and skills. With Hydraulic Disc Brakes being your bike's most critical safety mechanism, all steps within the manual must be taken. If you are unsure about the actions, it would be best to get your local SRAM dealer to perform the installation.

There are different manuals for Road and MTB; they can be found below:

Some tips for the process:

- Brake or DOT grease is required and necessary for barb and olive installation. This will allow for correct barb installation without the risk of any fluid leakage or hose binding.

- Hydraulic line cutters are a must! Be sure to use a hydraulic line cutter, and never use derailleur housing cutters or snips without a blade. This ensures that the hose is cut cleanly and the compression fittings can be installed fully without the risk of long-term damage to the hose. Non-hydraulic line cutter tools will compress the hose, causing ovalization. This ovalization is where fluid bypass could occur, resulting in injury or death.

- Compression nuts have a higher required torque than may be anticipated. Use a torque wrench set to 8Nm for best results. The high torque intends to crush the olive and create a metal-to-metal seal, so you may feel like something is yielding when tightening the compression nut - this is a good thing in this case!

- Please visit your local bicycle store if you are unsure of any steps. If you are unsure of successfully completing the brake line installation procedure, do not hesitate to have your local shop assist. Brakes are a safety item; maintenance must be accurately completed to ensure reliable performance. Failing to complete the installation successfully can lead to the risk of injury or even death.

- Follow the minimum bend radius guidelines set in the manual. Otherwise, your hose could become damaged. Familiar places for damage are where the hose enters the frame by the headset, internally routed handlebars, and the bottom bracket.

Looking to learn more?

We have two other brake articles to help riders with getting the right spare parts for their SRAM Brakes.

SRAM has fantastic learning resources, such as our service website and SRAM Tech YouTube channel.